SERVICES

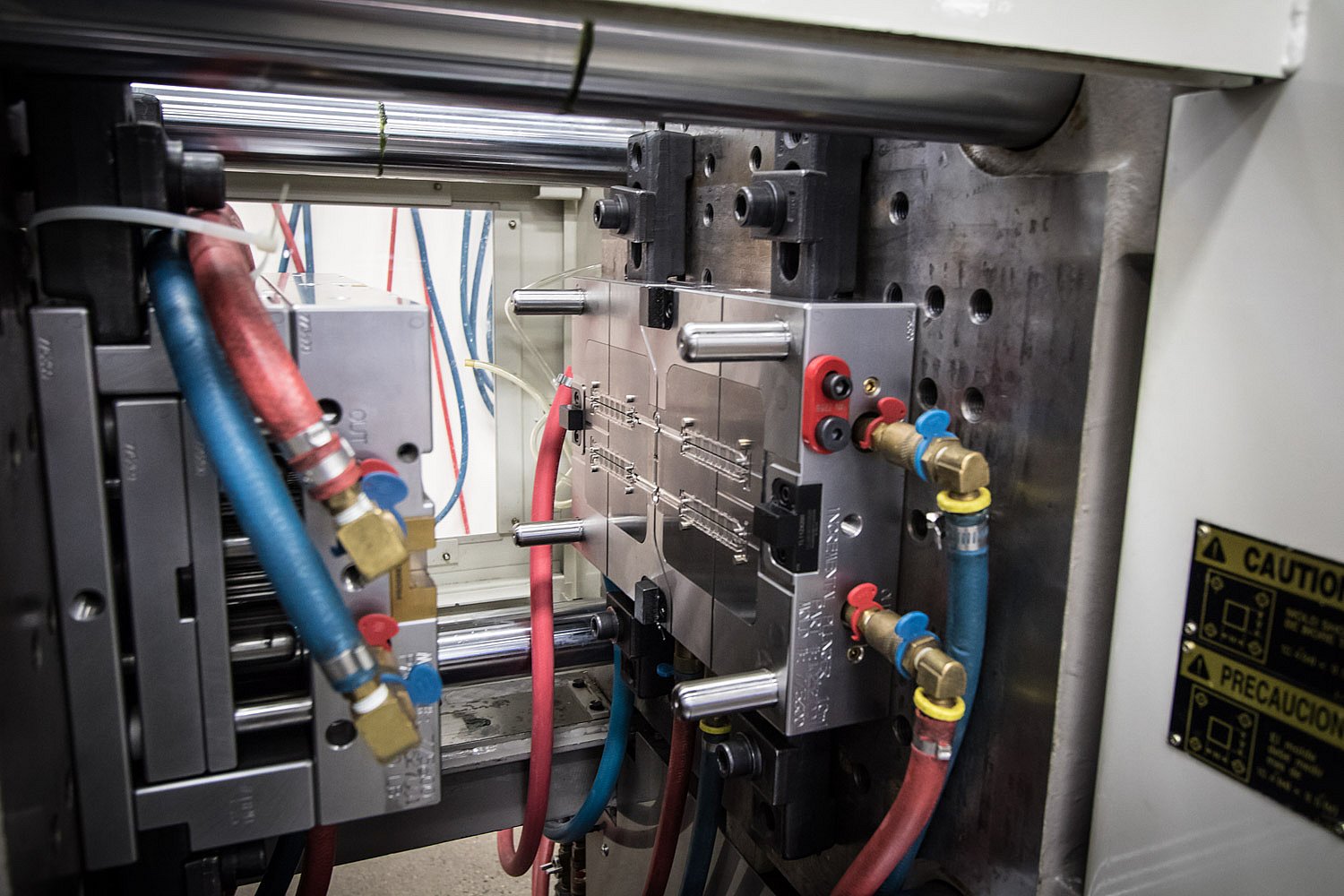

Injection Mold Sampling

Mold-Tech focuses on production-ready molds, saving our customers time and money. In-house sampling allows for needed mold adjustments to be made quickly and efficiently. A dedicated sampling engineer is on staff to sample molds according to customer requirements. Your injection mold is delivered ready to run.

Equipment

- Arburg Allrounder 370A 500-70 (55-Ton) Molding Machine

- 0.74oz Barrel

- Tie Bar Spacing: 14.56 x 14.56

- 2oz Barrel, All Electric

- Tie Bar Spacing: 18.1 x 16.1

- 2.8oz Barrel, All Electric

- Tie Bar Spacing: 20.1 x 18.1

- 10.3oz Barrel, 15.3oz Barrel

- Tie Bar Spacing: 24.80 x 24.80

In-House Mold Sampling

In-House Mold Sampling

- Aux Equipment:

- Desiccant Dryers (AEC, Novatec)

- Chillers (AEC, Temptek)

- TCUs (AEC, Advantage)

- Wittman Tempro Plus D 360F TCUs

- Wittman Sprue Pickers

- RJG eDart

- Hot Runner Controllers

- Plastic Granulators

- Denver Instruments IR-60 Moisture Analyzer

- Denver Instruments PI-114 Analytical Balance

If you need high-precision injection molds for complex parts, Mold-Tech can get the job done – first time, every time...

…And get you into production fast!