Mold-Tech Inc Capabilities

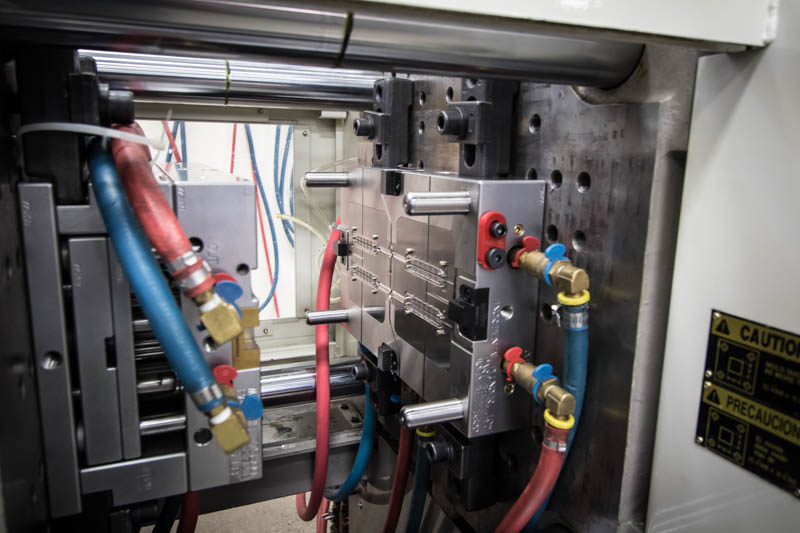

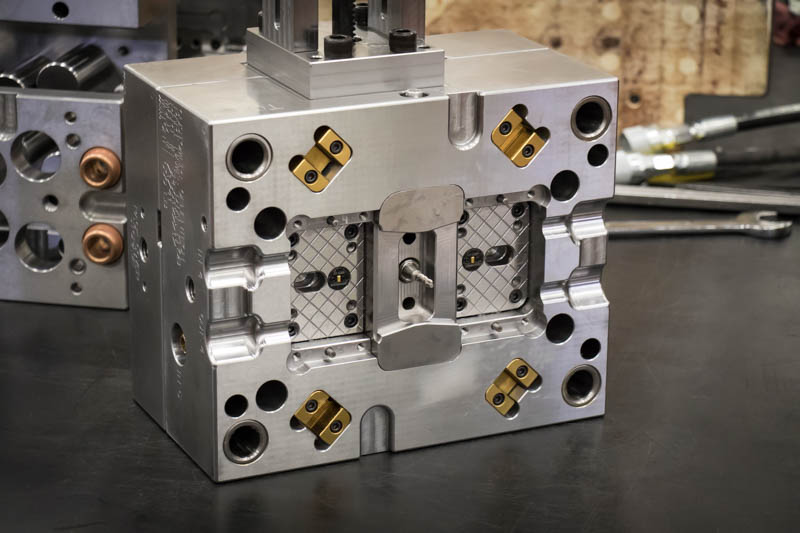

Design, build and sample precision injection molds for manufacturing plastic, metal and silicone components

- Established in 1978

- Located in Albertville, MN

- 24,000 Sq. Ft Manufacturing Facility

- Over 50 employees

- 2-Shifts

- Privately Held, S-Corp

- 6,000 lb crane capacity

- ISO 9001 Compliant

- ITAR Registered

- On-time Delivery

Serving Molders and OEMs in the following industries:

- Automotive

- Consumer Products

- Defense

- Electronics

- Medical/Dental

- Surgical Device

- Telecommunications

Design and Engineering:

- Dedicated Project Management (Single point of contact)

- Full In-house mold design

- Revision Level Control

- 3D Solid Modeling

- Design for Manufacturing

- Molding Simulation/Mold Flow

Injection Mold Types:

- Prototype

- Bridge

- Multi-Cavity

- Hot Runner

- Auto Unscrewing

- Insert

- In-Mold Decorating

- Micro

- Metal Injection (MIM)

- Liquid Silicone Runner (LSR)

- Shuttle

- Multi-Shot

- Stack

- All Mold Building Support Services, Revisions, Repairs

In-House Operations including:

- CNC Machining

- Design

- Electrode/Graphite Milling

- Soft Milling

- Hard Milling

- Mold Base Manufacturing

- Sink EDM

- Wire EDM

- Grinding

- Mold Repair

- Laser Engraving

- Laser Welding

- Sampling/Mold Tryout

- Metrology/First Article Inspection

- Custom End-of-Arm Tooling

On Time, Every Time

Our customers trust that we will meet or exceed their delivery requirements and provide exceptional support for the life of the program.